Efficient farm machinery operation is dependent on a properly designed and correctly set tractor-and-equipment configuration. Your tractor needs to be set up and programmed differently depending on whether you’re using it for cultivating, planting or transporting, or whether you're using suspended or pulled equipment with it. Setting the appropriate weight using ballasting and selecting the right tire pressure can be easily done with the help of our calculators, thus improving efficiency, and saving you considerable expense. And obviously this isn’t just limited to tractors: we also provide you with valuable information on how to best configure your planting equipment and your KITE Jet systems.

By correctly adjusting the tractor's weight, it is possible to achieve effective matching between the tractor and the implement, i.e., to balance the implement’s load characteristics with the tractor’s power output. The pulling performance is essentially determined by the engine power, the adhesion factor and the adhesion weight, which are always set by the operator. If ballasting is faulty, the amount of fuel burned unnecessarily will increase in line with the percentage increase in slip.

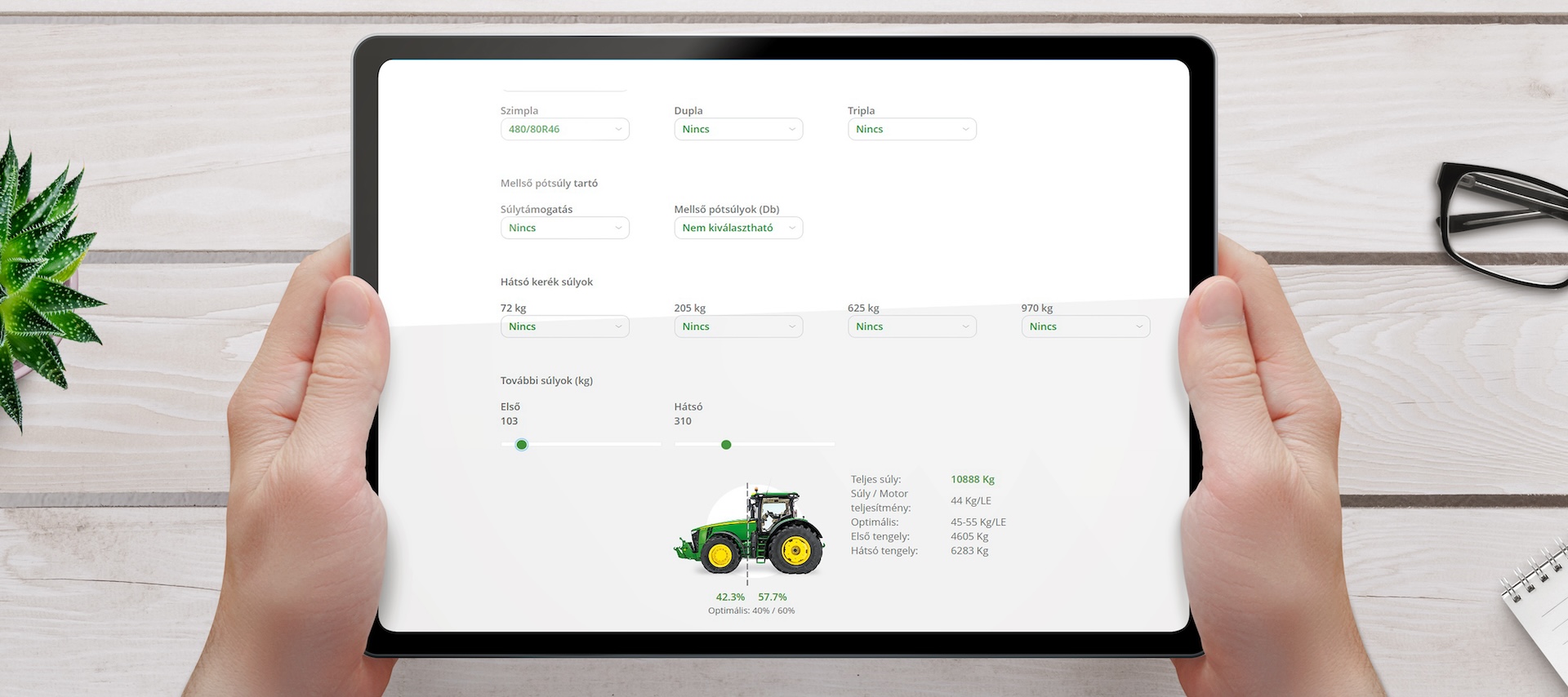

John Deere recommends that tractors should be ballasted between 45-55 kg/HP, but the maximum total weight as described in the Operation and Maintenance Manual should not be exceeded. Appropriate ballasting can be determined based on the correct ratio between wheel slip, operation speed, and engine load.

After selecting or entering data, the apps perform the necessary calculations, allowing you to quickly and easily calculate the settings required for the operations concerned.

If the machine is set up correctly, the costs of operation will amount to precisely the costs that are essential to do the job at hand, and no more.

Correct ballasting will allow you to reduce fuel consumption due to wheel slip or carrying unnecessary weight.

Optimal axle loading reduces soil compaction, thereby increasing the efficiency of your production.