In a world where agriculture is developing at a breathtaking pace, efficient and effective operation of machinery is key to maximizing productivity and profitability. Today’s modern machines require a wide range of knowledge and experience to operate them optimally. Whether you're a small farm or a large agricultural company, Precision Machine Operation Services can help you improve fleet performance, optimize maintenance, unlock the digital potential of your machinery and monitor the operation of your farm. Our experienced machine operation support team has in-depth knowledge of the latest technological developments and best practices in machine operation. Working together with you, our colleagues can help you realize the full potential of your agricultural equipment!

John Deere Planter Diagnostics and Calibration

The precise and properly timed planting is one of the most important technological steps during the production. Considering that you only have about six days for planting, it is very important to have your planter technically primed and inspected before the season to avoid any major downtime due to malfunctions. On the planter many factors are affecting the quality of the job, such as the integrity of the frame, the setting of row spacing, the condition of tubes, drive system, hydraulic system, planting monitor and control unit, but probably the main issue is the vacuum hoses and the seed meter unit. During calibration, each seed meter unit is mounted on a calibration bench, which is used to determine the accuracy of it, and the number of doublings and skips. A worn, not properly sealed seed meter unit can be 95% accurate compared to a right one which should be at 99%. During the diagnosis, recommendations are made for the replacement of wearing parts, which helps to maintain a uniform planting distance across the entire working width of the machine.

JOHN DEERE PLANTER DIAGNOSTICS AND CALIBRATION FOR SEED

The seed may widely vary in size and shape either in one bag. This discrepancy highly effects the quality of the planting but with the right settings it is possible to handle it. In the case of seed calibration, we install a seed meter unit on the calibration bench, where we identify the optimal settings for all varieties, in order to make a recommendation on the planting disc, vacuum value and working speed to be used during planting. This gives the machine operator a good reference point for the planting, so that it can begin more smoothly.

PRE-SEASON CLASSROOM AND PRACTICAL TRAINING FOR EQUIPMENT OPERATORS

Both technically and digitally, agricultural machinery has changed so much in recent times that machine operators need to have a large and complex knowledge base to use the machines and carry out the jobs they are entrusted with efficiently and to a high standard of quality, without any malfunctions. This process is further complicated by the fact that some of the machine operators are likely to be replaced and therefore a new workflow must be implemented and documented for them. The aim of this service is to improve the technical and IT skills of machine operators before the season, so that during the season they can perform their work efficiently, routinely, with less downtime and to the highest possible standard, preferably without breakdowns due to machine operation.

PRE-SEASON TRACTOR AND IMPLEMENT CHECK

We help our partners in setting up the proper tractor and implement combination. It’s important to ensure that the implement is properly coupled to the tractor, with all electrical and hydraulic lines correctly connected. And it’s important to set the right track width and to operate with the correct engine and transmission settings. The improper combination will lead not only to higher fuel consumption and breakdowns but damages the whole production cycle.

BALLASTING RECOMMENDATION

The correct ballasting is different for each tractor-implement combination, as it must be set differently for spring seedbed preparation, autumn tillage or for transportation. To do this, we use an axle-load measuring unit to make a ballasting recommendation for each work process and tractor-equipment combination. The agronomic consequences of improper ballasting are the soil degradation, excessive compaction and depressed emerging in tramlines. From technical side excessive tire wear, fuel consumption, final drive and axle damages will occur.

IN-SEASON MACHINE ADJUSTMENT, OPERATING RECOMMENDATION

In addition to the basic settings, we can help you to set up the machine and the machine combination under the given environmental conditions on your farm, so that you can operate your machines in the most optimal way.

DOCUMENTATION SETUP

We set up our partner's machines in accordance with the correct documentation, and we show the machine operator how to document the completed work precisely. The result of properly set-up documentation is that correct analyses can be created from the field-level data. The differences within the field can be used to draw conclusions that our partner can then use for his future plans. The correct documentation can be a good basis for filling in the farm logbook, or, if you use a utility program, you can generate a farm logbook with a single click.

PHYSICAL SCALING OF EQUIPMENT

The scaling of tractors and equipment is very important for correct documentation, but it is also essential for automatic steering because of the need for accurate connection lines, and for section-controlled equipment because of the need for accurate sectioning or zone changing.

ANALYSIS OF HARVESTING LOSSES

We use special tools to analyze the losses of harvesters, and we set the combine to the optimal loss level in order to achieve maximum capacity, to improve field performance, optimize fuel consumption and improve the quality of the harvested crop.

MACHINE OPERATION FORECASTING (OPT. E. A.)

John Deere’s special predictive system that uses JDLink™ data to send warnings about cases such as incorrect machine settings, improper wheel slip and high fuel consumption.

CREATION OF MASTER DATABASE (FIELDS, MACHINES AND INPUT MATERIALS)

The uniform nomenclature of the input materials and fields used on the farm, and the correct entry of the tractor and equipment list as well as of the corresponding parameters are essential for the creation of accurate documentation data, and so it is important to set these data correctly in all tractors suitable for documentation. It is also possible to add these to the field boundaries based on the coordinates specified to us.

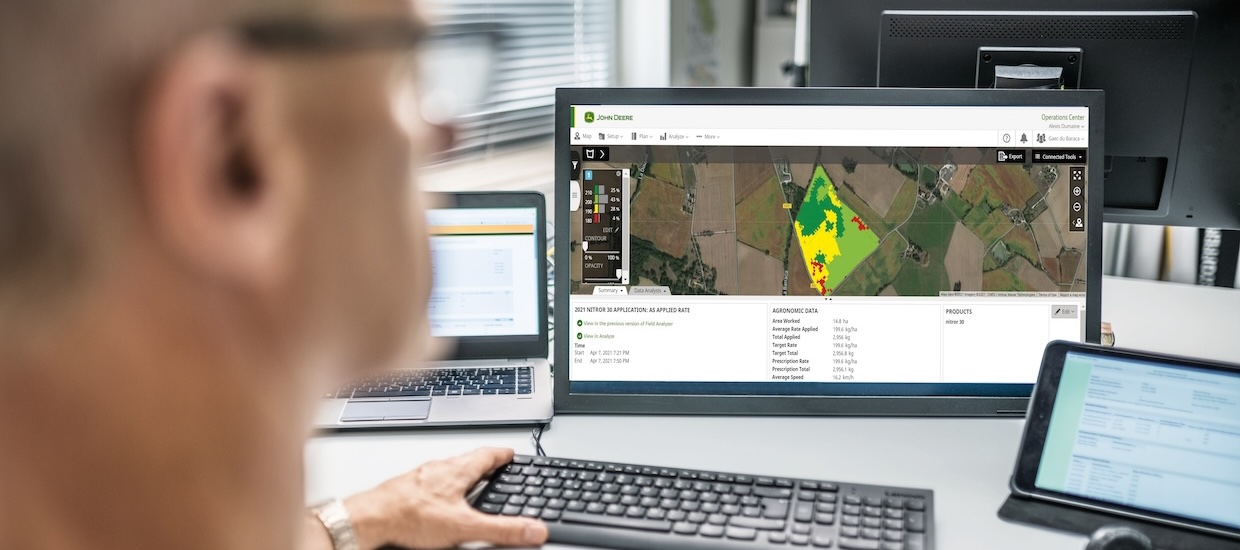

The Operations Center provides an opportunity for monitoring the planned applications. You can send the prescription maps on a USB device or online to the tractor monitors, where you can view the actual (“as-applied” or “as-planted”) maps documented by the machines even during application. The platform allows you to summarize the individual operations and give instructions to the machine operators for more precise applications using remote access.

magyar

magyar english

english srpski

srpski slovensky

slovensky